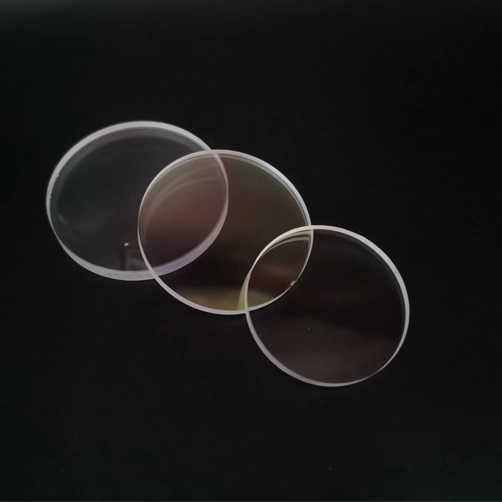

Si window and germanium window are the most commonly used infrared (IR) windows, the best working wavelength of silicon window is 3-5um, the best working wavelength of germanium window is 2-14um, it is one of the best substrates for filters.

Silicon window is a popular product for applications in the 1.2 - 7µm spectral range, and silicon's low density (half that of germanium or zinc selenide) makes it ideal for weight-sensitive applications, especially those between 3- applications between the 5µm range.

It has a density of 2.329 g/cm3 and a Knoop hardness of 1150, so it is harder and less brittle than germanium.

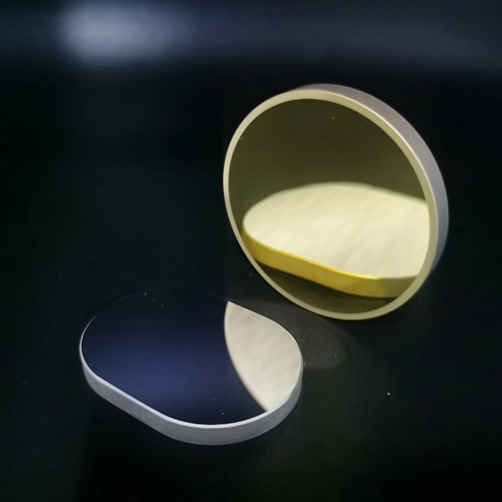

Germanium has good thermal conductivity and high extra-core hardness and strength, and germanium windows from professtional germanium window suppliers are often used in infrared systems that require higher strength.

Due to the high refractive index of germanium windows, an anti-reflection (AR) coating is usually required to improve the transparency of germanium windows. The common wavelengths of germanium windows are: 3~12um or 8~12um.

The transmission characteristics of germanium are extremely sensitive to temperature changes. The higher the temperature, the lower the transmittance. The optimal operating temperature of germanium windows is <100 °C.

The hardness of germanium windows is higher than that of magnesium fluoride windows, and germanium windows can be used in optoelectronics, infrared thermal imaging cameras, infrared laser systems, infrared optical instruments, infrared optics and other fields.

Silicon and germanium are both semiconductor materials used in various applications, including window technologies. The main difference lies in their physical properties and optical characteristics. Silicon windows offer better transparency in the visible spectrum but are less efficient in transmitting infrared light. On the other hand, germanium windows have superior infrared transparency, making them ideal for thermal imaging and infrared spectroscopy applications. However, germanium is generally more expensive and more fragile than silicon. The choice between silicon and germanium windows depends on the specific requirements of the application, such as wavelength range, cost, and mechanical durability.

Material Composition:

Silicon Windows: Silicon is a semiconductor and is abundant in nature. It is commonly used in optical components due to its transparency in the infrared region (1.2 to 7 microns). Silicon windows are suitable for a wide range of applications, including spectroscopy and imaging.

Germanium Windows: Germanium is also a semiconductor and is particularly transparent in the mid-infrared range (2 to 16 microns). Germanium is used in applications where sensitivity in the longer wavelength infrared region is crucial, such as thermal imaging.

Transmission Range:

Silicon Windows: Silicon is transparent in the shorter wavelength infrared region, up to approximately 7 microns. Beyond this range, silicon becomes increasingly absorbent.

Germanium Window: Germanium has a broader transmission range in the infrared spectrum, extending up to around 16 microns. This makes germanium suitable for applications requiring sensitivity to longer-wavelength infrared radiation.

Refractive Index:

Silicon Windows: Silicon has a higher refractive index compared to germanium. The refractive index affects how light is bent or refracted when passing through a material, influencing the design and performance of optical systems.

Germanium Windows: Germanium has a lower refractive index compared to silicon, and this can be advantageous in certain optical applications.

Mechanical Properties:

Silicon Windows: Silicon is a hard and brittle material, which can impact its durability and handling characteristics.

Germanium Windows: Germanium is a relatively soft material, making it more susceptible to scratching. Care must be taken in handling germanium optics to

As a optics manufacturing company, TC Optics is committed to manufacturing windows, spherical lenses, aspherical lenses, prisms, filters, reflectors, with 115 employees, we have the ability to carry out complete designs in our own factory, produce optical components and A finisher for assembling lenses. Welcome customers from all over the world to visit and consult.