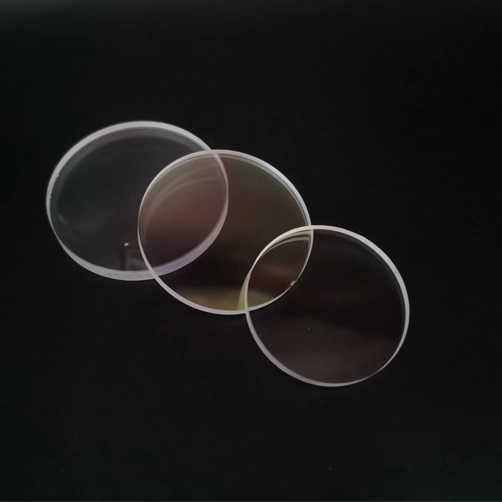

Optical windows are used as viewports to protect optical components, instruments or other components in lasers, in some applications optical windows need to withstand harsh environmental conditions and provide a high level of performance and reliability.

Sapphire windows have several unique properties that make them ideal for these applications.

1. Synthetic sapphire, the single crystal form of Al2O3 is one of the hardest materials (9 Mohs hardness), due to its structural strength, the sapphire window can be made thinner than other ordinary optical windows and has better light transmission properties.

2. High thermal stability and excellent thermal conductivity make sapphire windows suitable for high-power applications, and the loss of sapphire windows is smaller than other ordinary optical windows.

3. Compared with most optical windows, sapphire windows can withstand higher temperatures with zero degradation.

4. Due to the high dielectric constant of sapphire, the sapphire window is very stable and resistant to strong acid erosion.

5. Sapphire windows offer broadband transmission from UV to mid-infrared (0.15µm-5.5µm), all these unique properties make sapphire windows an ideal material for extreme mechanical, chemical and optical applications.

Sapphire optical window lenses can be widely used in various fields such as security, car wear, digital cameras, lasers, optical instruments, etc. With the continuous development of the market, lens technology is becoming more and more widely used.

1. The principle of hydration polishing and hydration polishing of sapphire optical windows is that the friction between the polishing disc and the sapphire surface during the machining process of the ceramic polishing machine, the contact point generates high temperature and high pressure, and the atoms on the sapphire surface are activated.

Use superheated water vapor molecules and water to act on the surface to form a hydration chemical reaction layer on the interface, and then use the superheated water vapor to remove the hydration layer on the sapphire surface by the friction force of the two, so as to achieve ultra-precision machining surface.

2. The principle of laser polishing and laser polishing of sapphire is through the thermal and photochemical effects of laser and sapphire, which can be divided into two methods: cold and hot polishing.

Cold polishing uses short-wavelength lasers to chemically decompose and remove materials. After the sapphire surface material absorbs light molecules, the surface material structure will be destroyed, so that the surface material leaves the body to achieve material removal.

Thermal polishing of sapphire windows generally uses continuous long-wavelength lasers to remove surface components of materials by melting, evaporation, etc.

However, the thermal temperature gradient is large, and the thermal stress is large, which is easy to cause cracks and surface roughness, which is more suitable for rough polishing.