Due to its special material, the window sheet has the advantages of infrared penetration, electrical insulation, corrosion resistance, and intrinsic safety. It is especially suitable for installation on high-voltage switchgear, easily realizes infrared imaging temperature measurement of switchgear, and completely solves the hidden danger of overheating of high-voltage switchgear contacts.

1. Intuitive: transparent ultraviolet, visible light, infrared, suitable for all current infrared thermal imagers, infrared spot thermometers, ultraviolet thermal imagers;

2. Safety: The use of windows can avoid damage to users caused by electromagnetic radiation, high voltage, high temperature and other harsh sites, and safely conduct live detection of the contact temperature of electrical cabinets and various high-temperature equipment;

3. Fast: It only takes a few minutes to install and transform the electrical cabinet, and it is easy to open the protective cover after installation, which can quickly observe many targets and conduct internal inspections;

4. Cost saving: Using windows, users can conduct preventive inspections on dangerous areas without interrupting and interfering with the operation of the equipment, and do not need to perform power outage maintenance, thereby saving a lot of expenses;

5. No special maintenance required: it can be used for more than 10 years without external damage.

As an excellent filter material, sapphire has good wave transmittance in the ultraviolet, infrared, and visible light bands (wave-transmitting materials are materials that can transmit electromagnetic waves and hardly change the properties and energy of electromagnetic waves).

It has a series of excellent physical and chemical properties such as high strength, high hardness, high temperature resistance, friction resistance, corrosion resistance, good light transmission performance, and excellent electrical insulation performance.

Therefore, sapphire crystal can be widely used in infrared and ultraviolet windows of aerospace instruments, blast furnace temperature measurement windows, solar cell protective covers, watch mirrors, infrared military devices, scientific research, civil industry and window materials for high-intensity lasers.

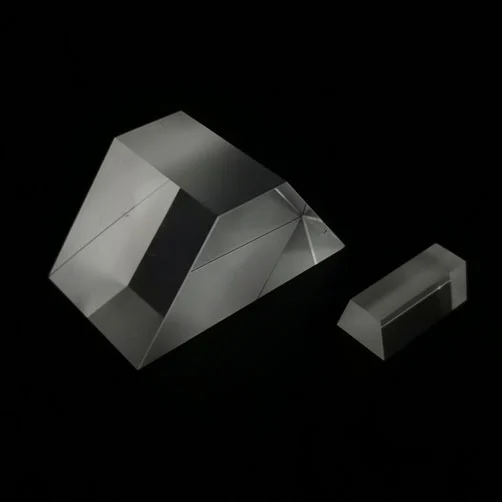

A window is a parallel plane plate typically used as a protective window for electronic sensors or detectors of the external environment, and does not change the magnification of the system.

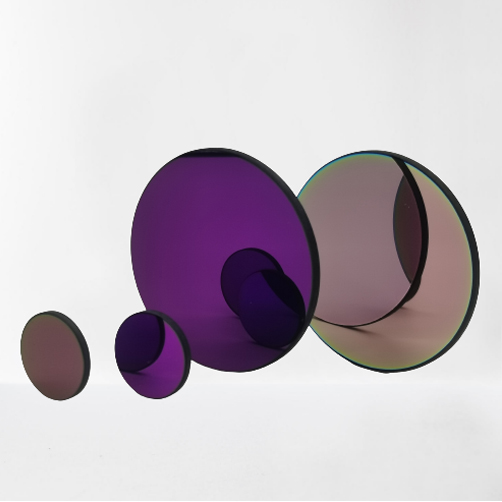

Base materials include various sapphire, optical glass, K9, UV fused silica, infrared fused silica, and crystal materials such as calcium fluoride, magnesium fluoride, zinc selenide, germanium, silicon, etc., and provide anti-reflection coatings, high-reflection coatings, spectroscopic Various optical coatings such as film and metal film.

Broadband anti-reflection coatings can be used in ultraviolet, visible, near-infrared and mid-infrared wavelengths, and windows made of single crystal sapphire materials are called sapphire windows.

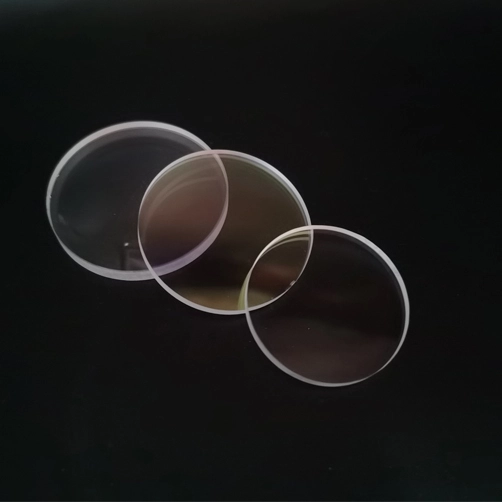

Sapphire window is a generic name, which itself includes sapphire optical window, sapphire protective window.

Sapphire optical windows refer to sapphire window products used in optical applications, which generally refer to imaging, detection, scanning, etc.

Because sapphire has the ability to transmit the full spectrum from ultraviolet to near infrared, sapphire optical windows can reduce the amount of glass used in optical instruments, greatly reduce the weight of equipment, and have a wide range of applications in aerospace and other fields.

However, the transmittance of sapphire material is only between 82-85%. In order to improve the transmittance of a specific wavelength band or prevent the transmission of a specific wavelength band, it is often necessary to perform a specially designed coating treatment on the sapphire optical window.

In order to make sapphire optical windows meet higher requirements, higher requirements are also put forward for the processing of sapphire optical windows.

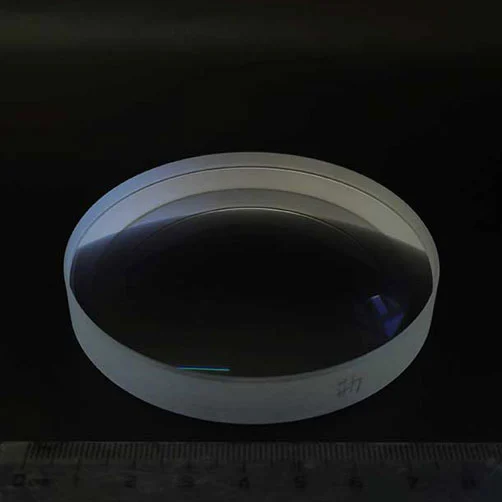

First of all, in order to ensure the consistency of spectral transmission, it is necessary to ensure the parallelism of the sapphire window (that is, the consistency of both sides to solve the optical path problem);

Secondly, there are also strict requirements for the flatness (surface type) of any plane. The flatness is required to be within the nanometer range, which is called the wavelength optically, and is generally required to be within 1/4 wavelength.

The sapphire protective window is a window product used to protect the user or the contents of the container by utilizing the characteristics of sapphire pressure resistance, scratch resistance and high temperature resistance.

Due to the extremely high hardness of sapphire, it has stronger compression resistance and scratch resistance than other glass products. The protective windows processed with sapphire are often used in deep water, oil fields, flammable and explosive occasions, high-pressure containers, Vacuum containers and other fields.

At the same time, sapphire can withstand a high temperature of 2030 ° C, and is also often used in high temperature containers.

As can be seen from the above, sapphire window is a common name, and sapphire optical window and sapphire protective window are exclusive names for different applications of sapphire.