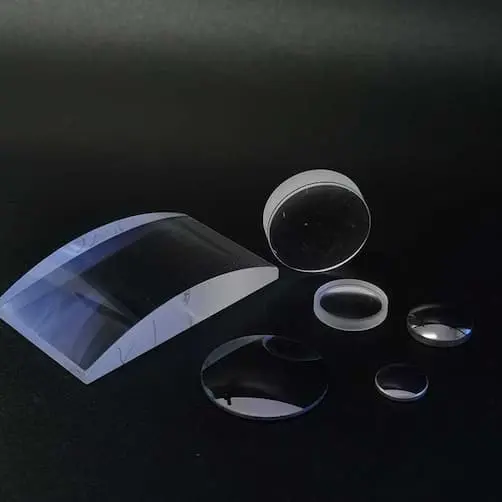

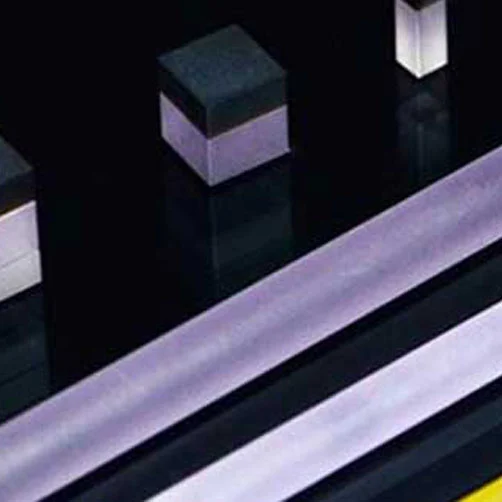

At present, mirrors, prisms, lenses, windows, filters, gratings, and other optical components are used in laser processing, life sciences, machine vision, optical communications, laser beauty, aerospace, education and scientific research, and other related fields. Choosing the appropriate Optical components are important, but their daily maintenance and cleaning methods among custom optical components are equally important.

First of all, when cleaning the optical components, try to operate in a dust-free and clean environment to avoid scratches or stains on the surface of the optical components. Commonly used tools and wiping reagents for cleaning optical components include cotton swabs, finger cots, gloves, tweezers, air guns, high-quality lens cleaning paper, wiping cloths, reagent-grade isopropyl alcohol, acetone, deionized water, etc. Different cleaning products are available Their respective special cleaning applications. Gloves and finger cots can isolate water, oil, dust, etc. on the hand from the surface of the optical element; tweezers can easily pick up/clamp the optical element; the compressed gas sprayed by the air gun can effectively blow off the dust on the surface of the optical element; Deionized water, isopropanol, and acetone can effectively clean the surface of optical elements; lens wiping paper or wiping cloth can clean the optical lens without scratching or scratching the surface of the element.

For types of spherical lens, the dust can be blown off directly with an air gun. If there are watermarks, oil stains, fingerprints, etc. on the components that need to be further cleaned, lens cleaning paper and an appropriate amount of reagent-grade isopropanol or reagent-grade acetone can be used to apply pressure from the center of the component. And gradually clean outwards, while slowly rotating the lens until the watermark, oil stain, fingerprints, etc. are wiped off.

The same is true for flat optical components. Dust can be blown off directly with an air gun. If there are watermarks, oil stains, fingerprints, etc. on the components that need to be further cleaned, lens wiping paper soaked in detergent can be used to slowly drag the surface of the components. If the method is just right, the cleaning agent will be evenly volatilized without leaving any streaks or spots.

1. The metal film layer is bare gold and cannot be wiped with the above method, it is better to do a good job of prevention

2. The optics component made by the scribing process or the microstructured optical components should be cleaned with dust removal by air gun as much as possible, and should not be easily wiped, so as not to damage the surface of the component. The above is the surface cleaning method of optical components. If you have any questions about the use of optical components, please contact TianCheng Optics. Our staff will serve you wholeheartedly.