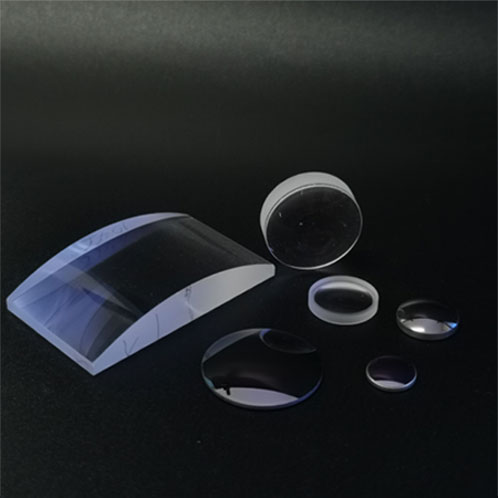

The spherical lens has a fixed curvature from the center to the edge, while the aspherical lens continuously changes from the center to the edge. In order to ensure optical performance in various lenses, it is necessary to correct aberrations.

If only a spherical lens is used for correction, many lens combinations are required to correspond to the technical requirements of the lens. The curvature radius of the aspherical lens changes with the central axis, so the aspherical lens can reduce the number of optical components used, thereby reducing the design cost.

Aspherical optical parts have become indispensable optical devices in the fields of military, civil and aerospace due to their unique optical properties and better imaging effects.

The aspheric surface processing technology is mainly divided into four parts: blank production, grinding and forming, polishing processing, and inspection of each process.

First, according to the design requirements of the aspheric lens, the spherical blank is processed, and the appropriate fixture is selected according to the size of the blank. The next step is the rough grinding, fine grinding and polishing of the aspheric surface processing.

After the aspherical surface is milled, the profiler should be used to detect the surface shape, and the deviation of the aspherical mirror surface should be corrected according to the detection results.

After repeated inspections and corrections, the important part of ensuring the surface shape accuracy of the aspherical lens comes to the polishing process.

At present, due to the wide application of optical components in various fields, the traditional processing methods of aspheric lenses have been unable to meet the needs of today's market in terms of processing efficiency and processing cost.

With the rapid development of ultra-accurate processing technology, the emergence of high-precision machine tools and the combination of computer technology have made a breakthrough in the processing technology of aspheric optical components.

This technology uses ultra-accurate milling machines to grind and shape optical element blanks, and then use computer simulation to determine reasonable polishing parameters.

Select the polishing parameters to calculate the motion trajectory and the dwell equation, and reduce the surface roughness of the aspherical element while ensuring the surface accuracy of the aspherical lens, so as to meet the processing quality requirements of the aspherical optical element.

TianCheng Optics CO.,Ltd is committed to manufacturing windows, spherical lenses, aspherical lenses, prisms, filters, reflectors, with 115 employees, we have the ability to carry out complete designs in our own factory, produce optical components and a finisher for assembling lenses. Welcome customers from all over the world to visit and consult.