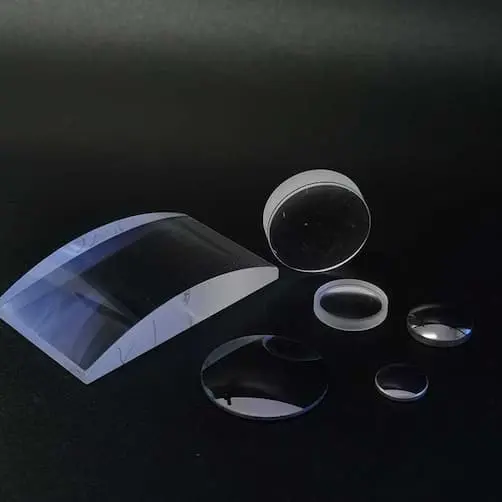

Optical window is one of the basic optical components in optics, and it is an optical flat plate that protects electronic components/sensors/semiconductor components in the light path.

The custom optical window does not change the optical magnification, and only affect the optical path in the optical path. Mechanical properties such as light transmittance, surface accuracy, thickness, parallelism, and substrate material are important parameters of the window.

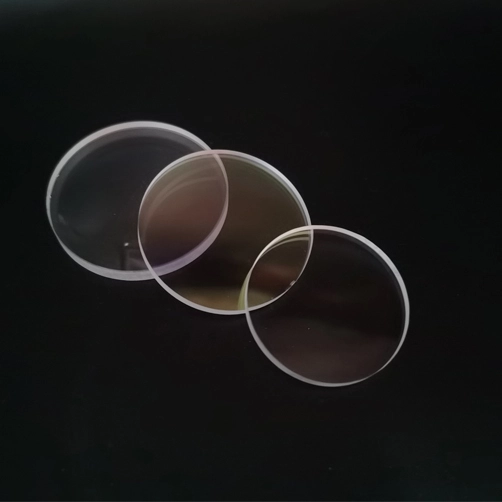

Optical windows are optical glass sheets that have been ground and polished to form two parallel surfaces. They can be used as protective elements between two environments, but they have little effect on the visible light passing through.

Commonly used coatings include anti-reflection coating (AR) and anti-scratch coating (AS), which can also be improved according to customer needs. It can be waterproof, dustproof and scratch resistant, and can be customized according to customer requirements.

Optical windows are the front protection sheets of optical systems. Optical windows are mainly used for packaging of CCD/CMOS chips, protection of optical instruments, measuring instruments and digital equipment, cover sheets on laser diodes, etc.

The various impurities in the optical window must be different from the optical window itself in terms of optical properties. When the light enters the optical window, various impurities will appear different from the surrounding optical windows in terms of reflection and refraction.

For example, when uniform light is perpendicular to the optical window, if there is no impurities in the optical window, the direction of the exit will not change, and the detected light is also uniform;

When the optical window contains impurities, the emitted light will change, and the detected image will also change accordingly. Due to the existence of impurities, stress concentration and deformation will occur around it, and it is easy to observe in the image.

If it encounters light transmission defects (such as cracks, bubbles, etc.), the light will be refracted at the defect position, and the intensity of the light will be greater than that of the surrounding area, so the light detected on the camera target surface will also be enhanced accordingly;

If it encounters light-absorbing impurities (such as sand grains, etc.), the light at the defect position will become weaker, and the light detected on the camera target surface is weaker than the surrounding light. Analyze the intensity changes of the image signals collected by the camera, The corresponding defect information can be obtained by the image features.

TianCheng Optics CO.,Ltd, an optical system precision parts manufacturer, is committed to the manufacture of windows, spherical lenses, aspherical lenses, prisms, filters, reflectors, and currently employs 115 people to produce optical components and finishers for assembling lenses. Welcome customers from all over the world to visit and consult.